Industrial Environments and the Summer Heat: What You Can Do

- By KD Equipment

- •

- 08 Mar, 2019

This is a subtitle for your new post

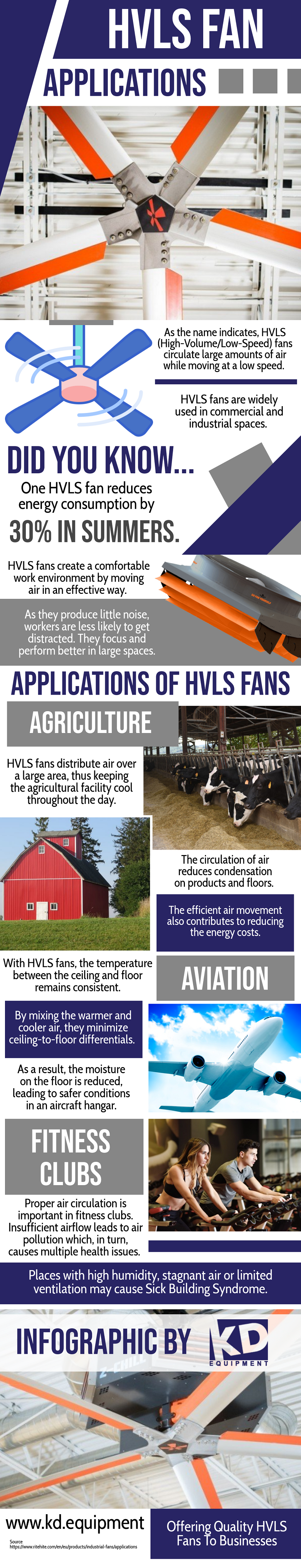

As the name indicates, HVLS (High-Volume/Low-Speed) fans circulate large amounts of air while moving at a low speed.

HVLS fans are widely used in commercial and industrial spaces.

DID YOU KNOW

One HVLS fan reduces energy consumption by 30% IN SUMMERS.

HVLS fans create a comfortable work environment by moving air in an effective way.

As they produce little noise, workers are less likely to get distracted. They focus and perform better in large spaces.

APPLICATIONS OF HVLS FANS

AGRICULTURE

HVLS fans distribute air over a large area, thus keeping the agricultural facility cool throughout the day.

The circulation of air reduces condensation on products and floors.

The efficient air movement also contributes to reducing the energy costs.

With HVLS fans, the temperature between the ceiling and floor remains consistent.

AVIATION

By mixing the warmer and cooler air, they minimize ceiling-to-floor differentials.

As a result, the moisture on the floor is reduced, leading to safer conditions in an aircraft hangar.

FITNESS CLUBS

Proper air circulation is important in fitness clubs. Insufficient airflow leads to air pollution which, in turn, causes multiple health issues.

Places with high humidity, stagnant air or limited ventilation may cause Sick Building Syndrome.

Infographic By KD EQUIPMENT

If you’re in the distribution or warehousing business, you know how crucial it is to maintain a stable temperature at your facility. Certain products need to be stored at specific temperatures, particularly if they’re perishable goods; the machinery in your facility also requires a specific temperature to perform optimally and last but not the least, the comfort of your employees is also a major consideration. And that’s not all; proper temperature control is also essential for reducing energy consumption and costs.

Keeping these things mind, we’ve compiled a list of measures that can help you improve temperature control in your warehouse.

Installing HVLS Fans

While most warehouses and storage facilities rely solely on HVAC systems for their temperature control needs, this approach can be quite expensive and can result in a lot of energy waste. While HVAC units are efficient at providing cooled or heated air to specific areas of a facility, they’re not good at optimizing the airflow.

This problem can be solved by installing High Volume Low Speed (HVLS) fans. These special industrial fans are engineered to move large volumes of air at speeds of 3 to 5 mph, which creates an evaporative, cooling effect. A single HVLS fan can serve an area of more than 20,000 square feet and can reduce temperature by up to 11°F . By circulating air efficiently around the facility, HVLS fans can help reduce the load on your HVAC system, which ultimately results in significant energy savings. HVLS fans can also significantly reduce humidity and allow for better warehouse temperature control.

Increase the Energy Efficiency of Your Loading Dock

Loading docks are among the largest contributors of heat/cooling loss in warehouses, with damaged dock doors being a major culprit. Damaged dock doors often have gaps in the frame which become an entry point for unwanted drafts. The HVAC system has to then work extra hard to maintain the correct temperature, which results in high energy bills.

If your dock doors are inefficient or worn out, consider replacing them with high-quality insulated industrial doors that can effectively keep out drafts and can hold up in the rough warehouse environment.

Furthermore, installing seals and shelters across your loading dock can also help in maintain a stable temperature in your facility. Dock seals and shelters allow trailers to compress to the perimeter of the dock door when they back into the loading bay. This effectively seals the gaps and prevents outside air from entering the facility.

With over three decades of experience in providing high-quality warehouse solutions, KD Equipment is one of the biggest names in the warehouse equipment industry. Based in Florida , we provide a wide variety of warehouse equipment including HVLS fans , air doors , and loading dock accessories. Get in touch with us for further information.

In recent years, the popularity of High Volume Low Speed (HVLS) fans has risen dramatically among industrial businesses, particularly those for whom temperature and climate control are important requirements. In addition to optimizing the airflow in your space, an HVLS fan will also help you make significant savings on energy costs.

How Do They Work?

HVLS fans work in quite a simple manner. Their long lightweight blades gently push large amounts of air downwards, where it travels along horizontally along the floor. This process keeps the air moving around the room in a circular motion at a stable speed, and prevents pockets of air sitting stagnant.

Low Speed Airflow Benefits

The primary advantage of keeping air moving at a slow speed is that it’s non-disruptive and the airflow optimization achieved is much greater compared to conventional high speed floor fans. Also, when large volumes of air are circulated around the room, it effectively counteracts the ‘rising heat’ effect, and maintains a uniform room temperature. In large, cavernous spaces, HVLS fans can potentially reduce the temperature from 7 to 11 °F .

Energy Efficiency

HVLS fans work in combination with HVAC systems or the natural ventilation. However, while HVAC systems are efficient at distributing air, they’re not good at mixing it. Since warm air rises, there can be a difference of up to 20 °F between the ceiling and the floor in tall, cavernous facilities. HVAC units often work extra hard to make up for this difference, which leads to a wastage of precious energy.

As we mentioned above, an HVLS fan allows constant circulation of air, which mixes air and removes the different layers of temperature from within it. This process is known as “destratification” , and it reduces the load on the HVAC systems, which naturally leads to lower energy consumption.

Selecting the Right HVLS Fans for Your Facility

When shopping for HVLS fans, it’s important to remember that not all products are the same. Owing to the drastic rise in demand, manufacturers of HVLS fans now offer products in a variety of sizes and specification, which means that you can now buy HVLS fans that are designed to optimize airflow to your specific requirements. So analyze the needs of your facility before you make a buying decision.

With over three decades of experience in providing high-quality warehouse solutions, KD Equipment is one of the biggest names in the warehouse equipment industry. Based in Florida , we provide a wide variety of warehouse equipment including HVLS fans , air doors , and loading dock accessories. Get in touch with us for further information.